The North-West University (NWU) continues to show its commitment to cutting-edge innovation and practical research solutions. The new STRIDE remote unit, which makes remote management of equipment and processes possible, easier and more accessible, is the latest business-ready technology to come out of the Faculty of Engineering’s venture, STRIDE. This advancement addresses real-world challenges faced in IoT-enabled industrial digitisation in sectors ranging from agriculture and higher education to mining and manufacturing.

JP van Deventer, project manager, says the STRIDE remote unit was inspired by the success of their ozone generator project.

The concept originated in 2020 during STRIDE’s work on ozone gas disinfectant systems. “We recognised the importance of remote control and monitoring to ensure the effective management of ozone applications. Since then, these ozone-generating units have been operating successfully using the same IoT technology. It saves time, reduces maintenance costs, increases uptime and improves efficiency.”

Now STRIDE has taken this innovation a significant step further.

“We found that there was a need, throughout industry, specifically for a flexible remote control and monitoring system. This is why we developed an in-house solution that could be integrated easily into our own systems, but also remain flexible enough to work across multiple industrial and research applications.”

A flexible, plug-and-play solution

The STRIDE remote unit has been designed with adaptability in mind. It can integrate seamlessly with four standard interfaces commonly used by industrial sensors and includes four relays to control equipment, manage power and enable detailed monitoring of equipment and processes.

Operating on a 220VAC or 12VDC input, the device provides real-time insight into temperature, power usage, operating time and maintenance requirements. All these are critical factors in preventing equipment downtime. This capability makes the technology ideal for applications such as assembly lines and machinery in manufacturing plants, coldrooms in produce-storage facilities, greenhouses and hydroponic growing systems in agriculture, but also in the digital transformation projects of smart offices, campuses and cities.

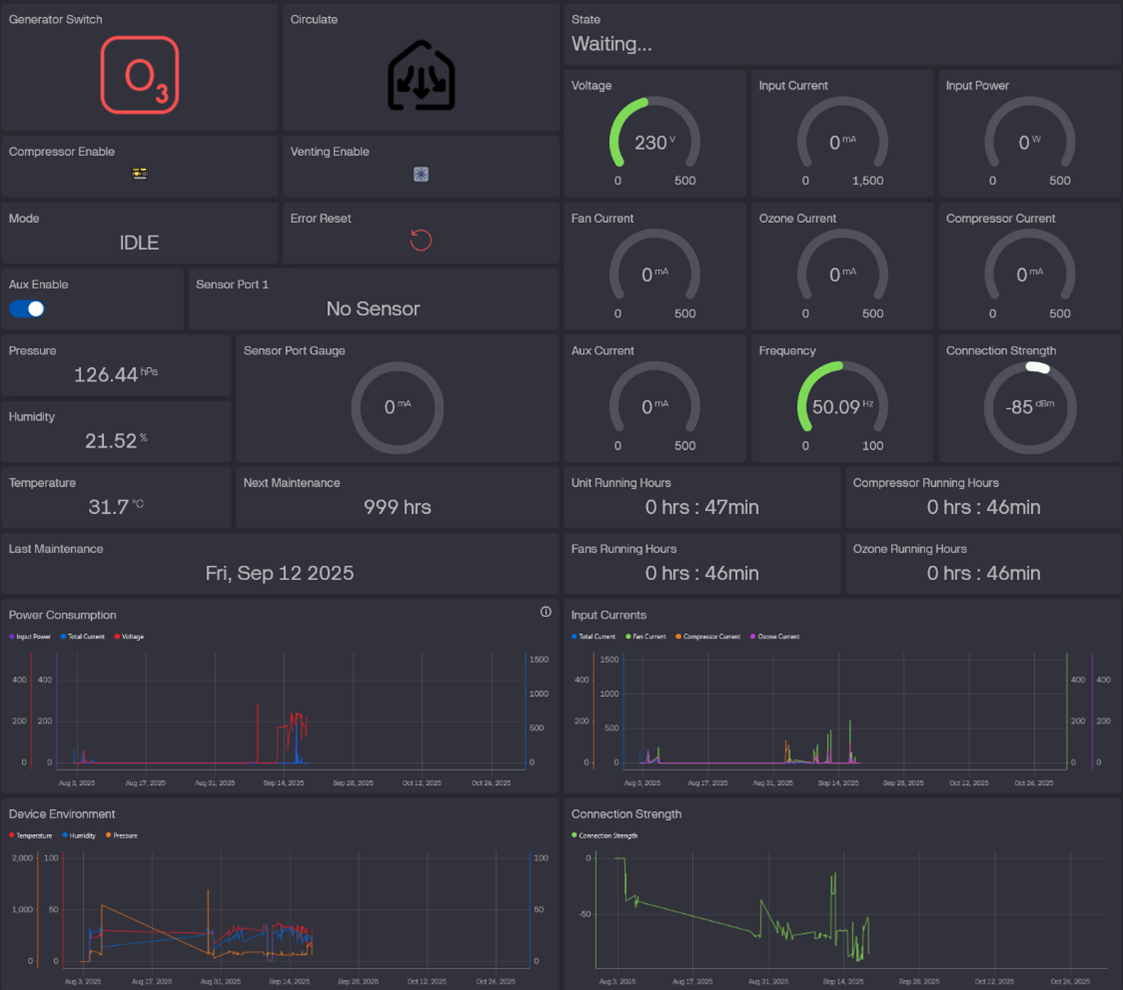

The unit features both basic and advanced interfaces. The basic interface allows users to check system status, identify errors and track service intervals, while the advanced interface provides detailed data, in graph form on voltage, frequency and operational indicators. The system is capable of storing and displaying historical data, allowing for trend analysis and long-term performance monitoring.

Wide range of applications

As mentioned, the unit is designed for use in a variety of settings that include, but are not limited to, agriculture and manufacturing. On smart campuses, it can be applied to inverter systems to provide IoT capability, allowing remote control and monitoring of battery voltages, health and state-of-charge (SoC), among others. Beyond academia, its applications extend to applications typically controlled with local Programmable Logic Controllers (PLC) like agriculture. The technology can easily expand the capabilities of these typical offline systems to IoT-enabled systems for more efficient utilisation and control of irrigation systems, greenhouses and water purification, among others.

JP says the unit’s flexible design allows it to be implemented anywhere it is needed, providing immediate fault detection and enhanced operational oversight.

Technology with purpose

The remote control and monitoring technology line developed by STRIDE is focused on simplifying automation without compromising functionality, JP says. “Our goal was to make automation as easy as possible, while still adding flexibility and expandability. The technology is plug-and-play and scalable, allowing users to modify or expand their operations without overhauling existing systems.”

From concept to creation

The development of the remote unit was a process of refinement and dedication. “This technology wasn’t built overnight,” JP notes. “We spent countless hours ensuring it meets our standards for reliability and performance.”

“At STRIDE, we believe that the phrase ‘it has always been done this way’ can become a barrier to progress,” he concludes. “We draw inspiration from traditional technology, but we are not afraid to rethink existing methods. That mindset allows us to solve problems in ways others might not consider.”

JP van Deventer

The interface of the STRIDE remote unit

![]()

The unit was designed to be compact and efficient