Christoff Briers is only one of the many success stories of North-West University’s (NWU’s) Faculty of Engineering. Today he is at the head of production planning at Simmer Engineering, an engineering company in Alberton that specialises in manufacturing.

According to him his passion for the manufacturing industry is to a great extent due to his exposure to and involvement in the NWU’s well-known solar car project.

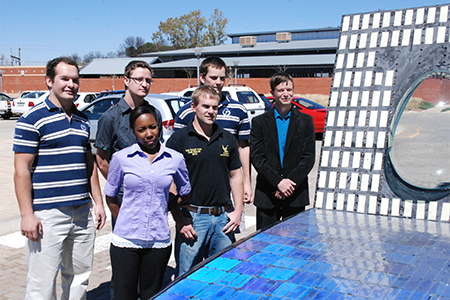

Christoff was one of only four students who worked on the first solar car initiative in 2012. “It was a madhouse,” he says. “I think we did not exactly know what we were letting ourselves in for. We had to build a solar car from nothing and compete against international competitors.”

Christoff says they were one electrical and three mechanical engineering students who became involved in this initiative under the leadership of Prof Albert Helberg. “My responsibility was the suspension, braking and steering system of the ‘Bat Mobile’ – as the media christened our black carbon fibre solar car.

“However, we did not plan for the car to be black – at that stage there was just not enough time to paint it, and we had to participate in our first Sasol Solar Challenge just like that,” he laughs.

The Sasol Solar Challenge competition is hosted in South Africa. Teams from across the world compete with their solar car technology to see which car drives the most kilometres from Pretoria to Cape Town using only solar energy.

Although the route from the starting line to the finish is the same distance for everyone, teams have to try and drive additional kilometres along the route in order to determine in the end which team’s solar car was able to drive the biggest distance in the given time.

During their debut journey in 2012, the NWU’s solar-car team came first in the Olympia class, and was crowned joint winners of the Fédération Internationale de l'Automobile’s Alternative Energy Cup.

This team also walked away with the safety award and the Spirit of Africa award – an enormous achievement in their first year of participating in the Sasol Solar Challenge!

In 2014 the team obtained an overall fourth place, and in 2015, during the Bridgestone World Solar Challenge in Australia, an 11th place. “I should also mention that at that time our solar car were the first solar car from Africa that was able to complete this gruelling competition,” he adds.

In 2012, while Christoff was still involved with the solar car project as a student, he started working as a junior engineer at a diamond mine at the same time. Something not every student is able to do! He was involved at the mine for two years before he decided to return to the manufacturing industry.

Currently, he works in conventional manufacturing, as well as manufacturing for the mining, railways, heating, ventilation and air conditioning industries. “My work basically involves making sure that the right quality parts are delivered to our clients on time. This includes production optimising, implementation of new systems, workshop planning and the coordination of activities in the production environment.”

If it hadn’t been for the exposure he had gained during the solar car project, he would probably have discovered his interest in the manufacturing industry only at a later stage. “My activities during the solar-car project involved a lot of conventional manufacturing and I was therefore able to gain knowledge in this field even before I started working,” says Christoff.

“This stimulated my interest to learn more about the industry. I enjoyed it so much to see how a functional part can be manufactured from a simple block of metal. This is my fifth year back in the manufacturing industry, and I will exchange it for nothing.”

Christoff says his winning recipe is that since his student days he has exposed himself to different disciplines, for example during the solar car project. “This also includes the ‘softer’ disciplines like how to work together in a team under pressure, and how to build relationships with suppliers. There were many nights that we did not sleep because we had specific targets to reach.”

He says that taught him that hard work is always rewarded. The NWU has world-class lecturers – most of them with their own success stories in the engineering industry. I salute the NWU for the exciting engineering career that still lies ahead for me.”

Christoff Briers (left) when he was involved in the NWU’s first solar-car project in 2012.