You will find innovation for new ideas, projects and devices in abundance at the North-West University’s (NWU’s) Faculty of Engineering – and the same applies when it comes to three students in Computer and Electronic Engineering.

Izak Adendorff, Gerno Visser and Duhan Janse van Rensburg were merely looking for something to do over the 2019 December holidays when they came up with the idea for building a unique 3D printer. In the nature of things these three do not attempt anything half-heartedly.

It all started with a question: “So, what are we doing in the December holidays?”. Gerno, a second-year engineering student, responded immediately and suggested that they build a 3D printer from scratch. This initiative then developed into a fully functioning CoreXY three-dimensional printer designed for business and industrial use.

“We were not satisfied with the quality and specifications of the available printers. All three of us have different printers, each with its own weaknesses. We decided to build a printer that could improve on all these weaknesses and could still be upgraded easily in the future,” says Gerno, the chief designer. “We chose the CoreXY building style as it has fewer moving parts, and it is therefore possible to print parts faster and at a higher speed.”

However, the process of building a 3D printer is not a simple one. After Gerno designed the printer with software, the team could already print plastic parts with their existing 3D printers, and the rest of the parts were imported from China.

“We waited almost two months before we received all the parts from China. Eventually Gerno could assemble the new printer at the beginning of January. By the middle of January we showed the first version to the faculty,” says Izak, the project manager and supplier of the parts.

These three engineering students are still working on the printer to find possible faults and repair them. Most of the items that are now printed by the team are the printer’s own parts, with the improvements that they made themselves. “The lack of quality of the parts was our main problem,” says Duhan, the co-designer.

Another problem the team encountered was funding. “It is difficult to attempt such a project when you are a student and you have to pay for everything yourself. Fortunately expertise was no problem. I could not ask for better people on my team,” says Izak.

Hobbies are something that these three students have in common. Between the three of them they have built many devices on an individual level to meet the basic needs in their own lives.

Duhan built a central locking system for his car, as well as a submersible pump that he can control with his cell phone. “I would like to become involved in product development in the automotive industry, not only because of my love for cars, but also because I think that there is still room for improvement in an industry that is still growing every year,” he says.

Izak is of the opinion that his genes are not programmed to sit still: “Since I could walk I have disassembled devices to use them in another way, of to reassemble them.” He has already built devices like a PACMAN watch and a Wi-Fi jammer. “The Wi-Fi jammer was initially made just to measure the strength of WiFi signals, but later on additional functions were added to ensure network security.”

Gerno lives out his passion for radio-controlled aeroplanes with the devices that he builds. “I have already built my own drone, which I am developing further.”

Every one of these young men has a sound knowledge of and background in the building of devices, but there was still a learning curve involved in the development of this 3D printer. Patience, tolerance and communication with people were skills that these three acquired in the end. “I gained much knowledge about interacting with people and systems to make the whole process of finding and buying parts cheaper and more effective,” says Izak.“Design and practice do not always work out in the way that you planned,” says Duhan, and he is grateful that he could use this opportunity to hone many of his skills.

This team of engineering students wants to encourage other students to devote their attention to their knowledge and passions in their spare time. “Visit websites like www.instructables.com and be inspired to learn something new,” says Izak.

What initially was a hobby in a December holiday, became a valuable service that the team can now provide to the public. You can contact Izak at 083 646 5656 for any 3D printing needs, of visit their website at www.fusion3d.co.za. This team is working at full speed to print various items on demand for the public.

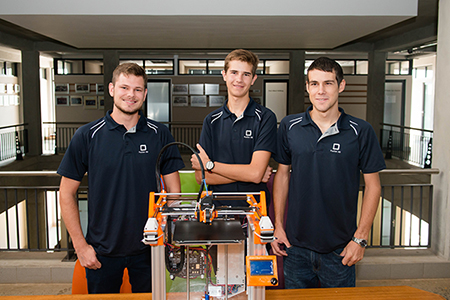

From left are Izak Adendorff, Gerno Visser and Duhan Janse van Rensburg.